Secure

In safety glass, the glass is protected from possible spillage by a safety film that is placed between the layers of glass. This film plays a key role in providing additional protection and safety in case of glass damage. Here are some details about it:

Safety film: Security film, used in safety glass, is usually made of polymeric materials such as polycarbonate or polyvinyl butyral (PVB). It is a flexible and durable layer sandwiched between two or more layers of glass.

Enhanced safety: The safety film acts as an additional barrier that holds pieces of glass together in case of damage or breakage. As a result, even if the glass is broken, the pieces of glass do not scatter and do not pose the same danger to people nearby.

Break-in resistance: Glass with security film is harder to break, making it more resistant to burglary. This increases the level of security in case of attempted theft or burglary.

Weather protection: Glass with a security film is also more resistant to weather conditions such as high winds and hail. Even if the glass is damaged by an impact, the film holds it together, reducing the effects of damage and preventing water from entering the building.

Reducing the risk of injury: With this film, the risk of injury from contact with sharp pieces of glass is significantly reduced. This is especially important in places where there is a potential risk of glass damage, such as schools, public facilities and public buildings.

Glass with security film is widely used in commercial and residential construction for its safety and security features. If damaged or broken, they remain integral, protecting both property and people from potential damage.

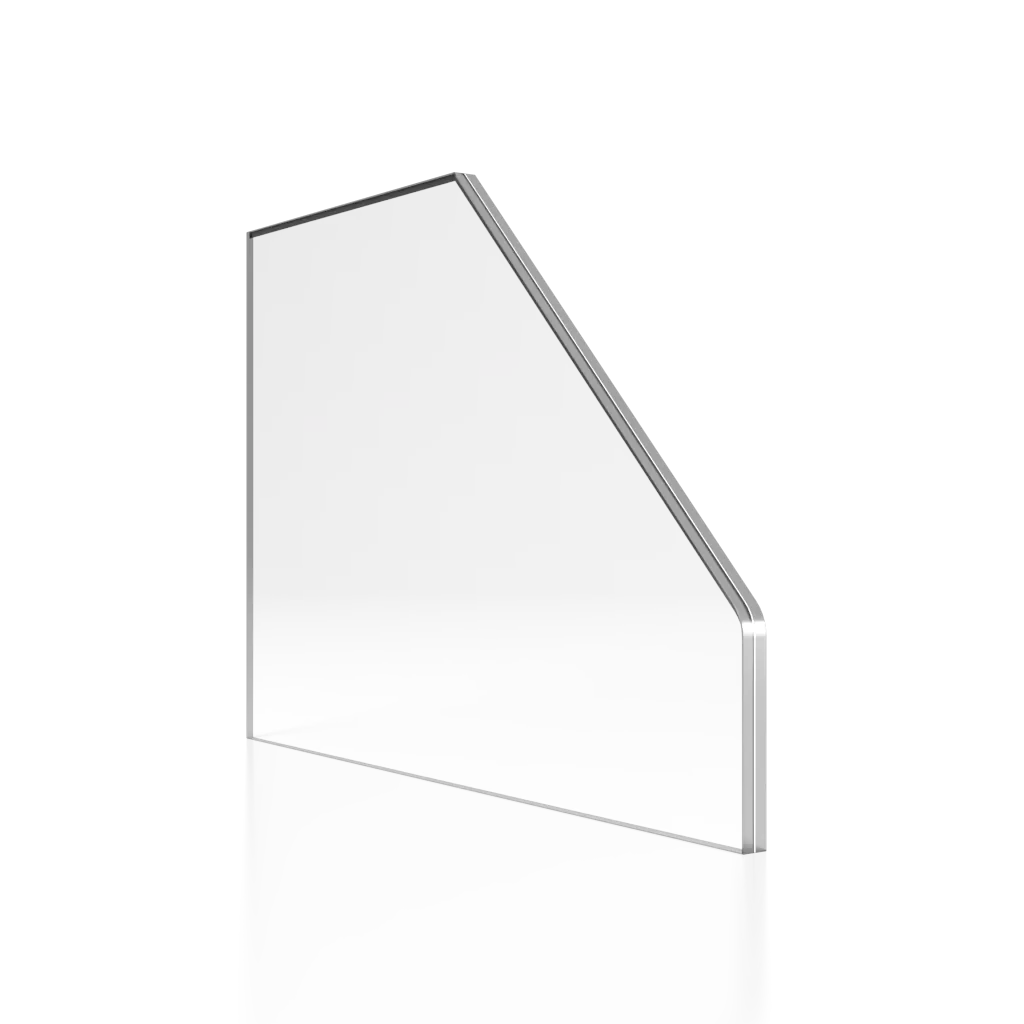

Available in three thicknesses

33.1 mm thick safety glass

44.2 mm thick safety glass

44.4 mm thick safety glass

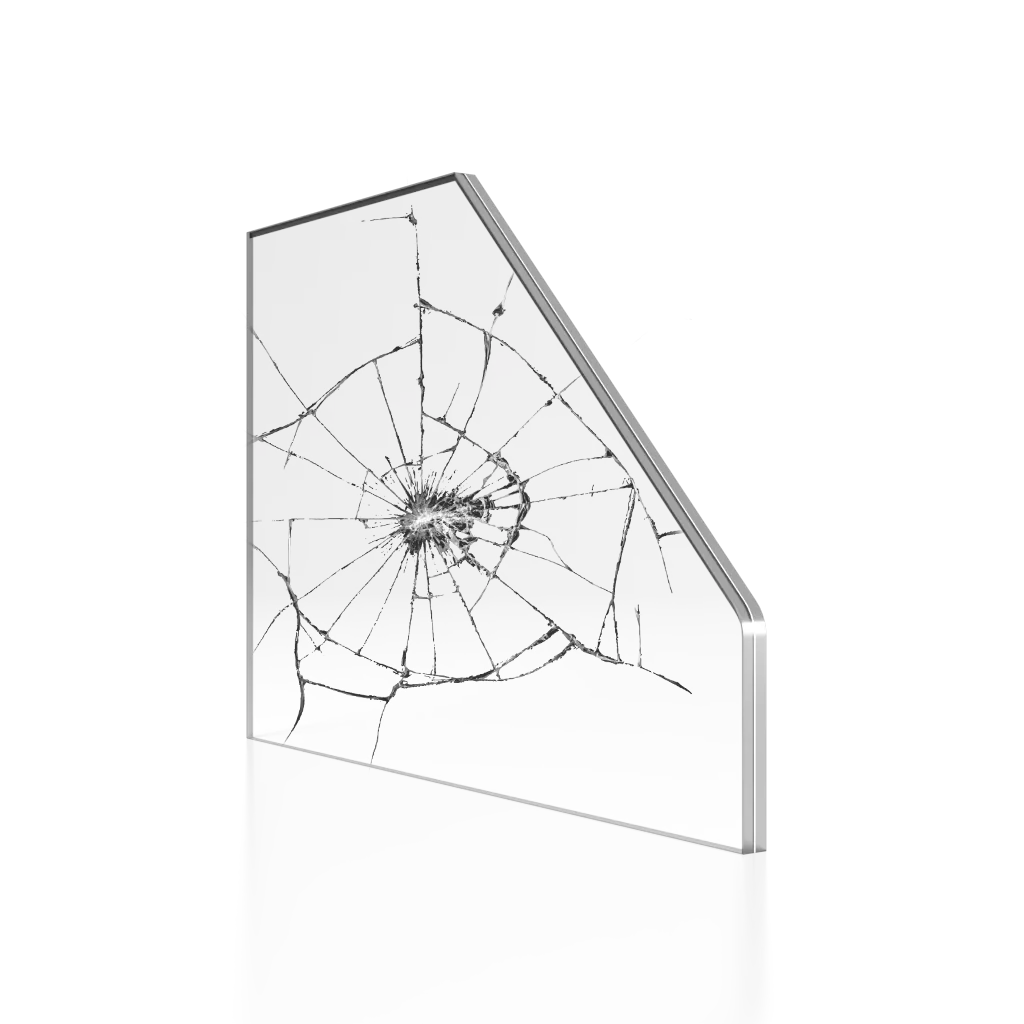

Breakage of safety glass

Safety glass

Safety glass after breakage

The breakage of safety (laminated) glass looks significantly different from that of ordinary glass. When laminated glass breaks, it does not shatter into loose, sharp fragments. Instead, the damaged glass usually remains adhered to a transparent PVB (polyvinyl butyral) film, which acts as an adhesive between the layers of glass. The most important features of broken safety glass can be found below:

- Cobweb of cracks: When such glass is struck, cracks are formed that spread radially and concentrically, forming a spider web-like pattern. The cracks are usually very dense at the point of impact, thinning at the periphery.

- The shards remain in place: Shards of glass do not fly away, as is typical with broken ordinary glass. Instead, each piece remains attached to the film, maintaining the relative integrity of the entire glass.

- Slight deformation: The impact site may show some deformation, where the glass is more concave or convex depending on the force and angle of impact.

- Transparency despite damage: Despite numerous cracks, the glass still remains mostly transparent, although its clarity is reduced in areas of damage.

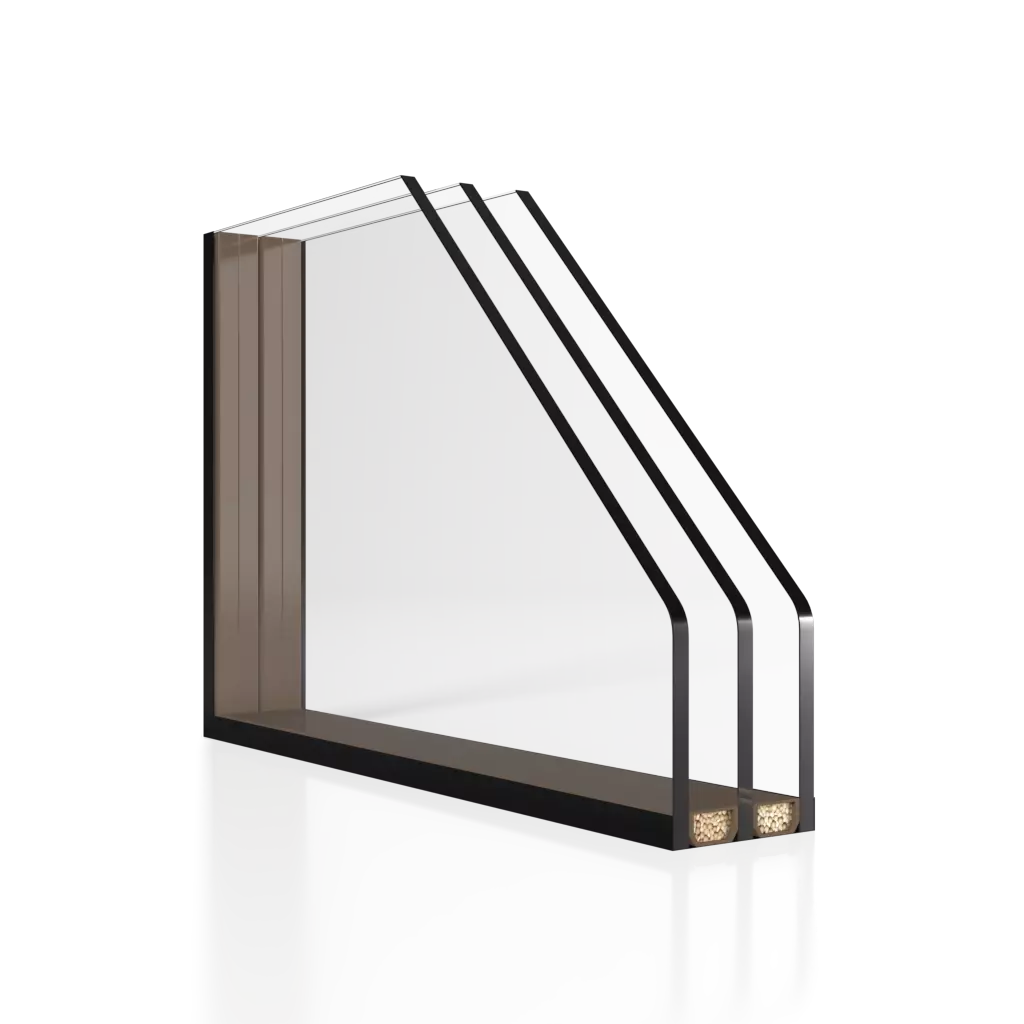

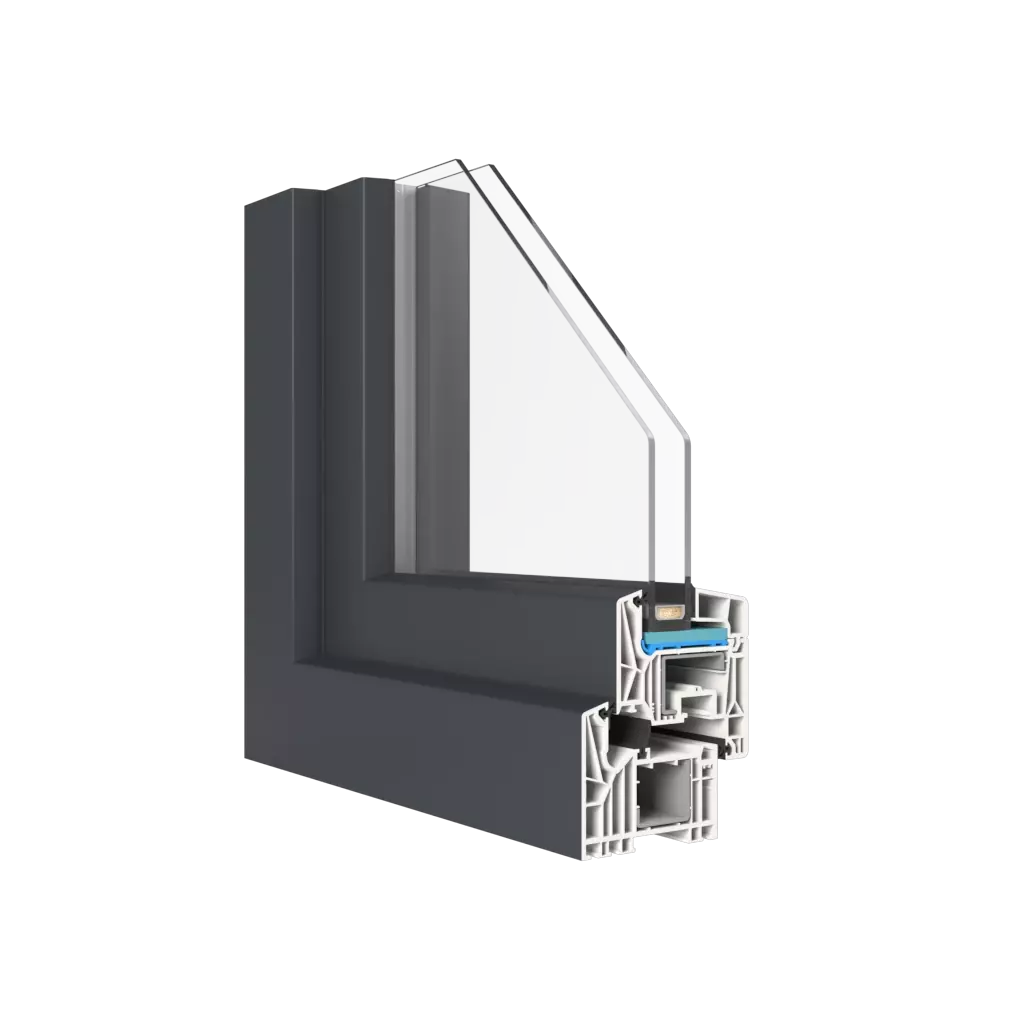

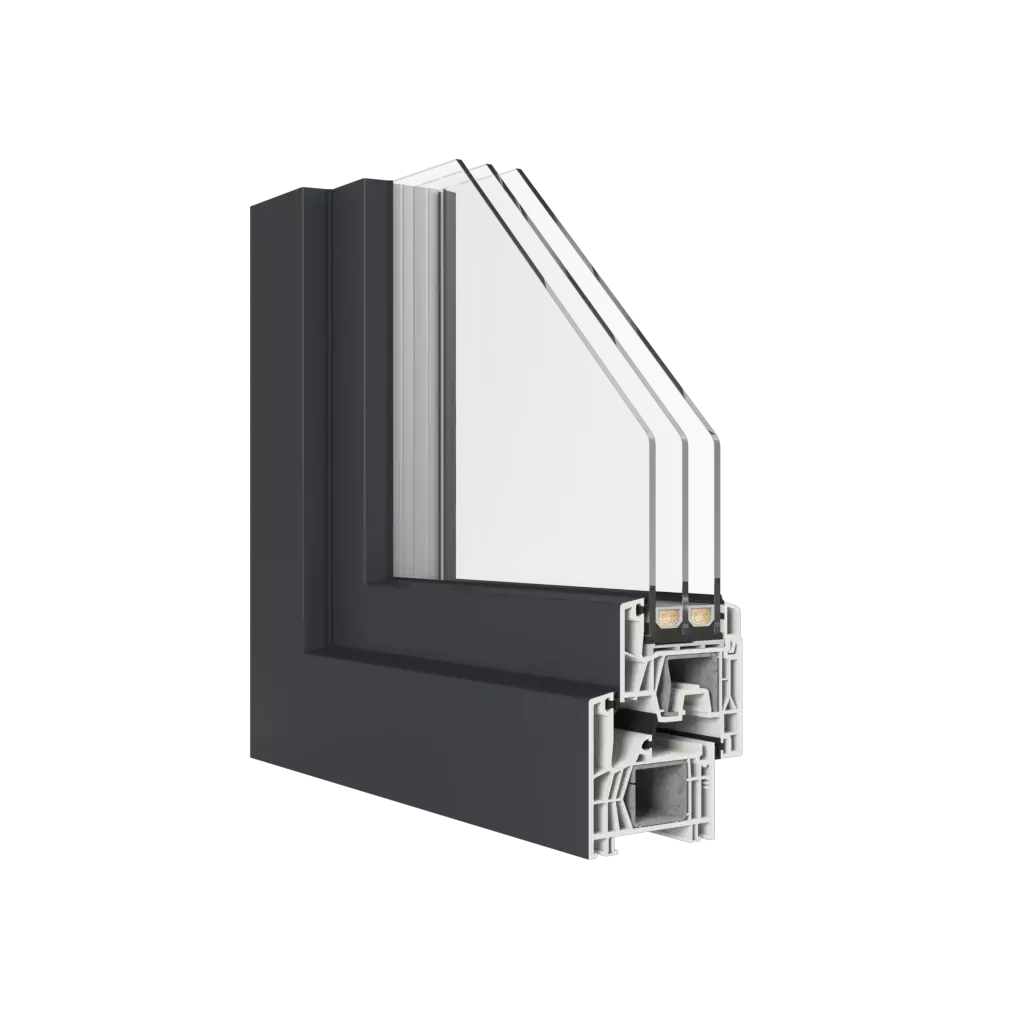

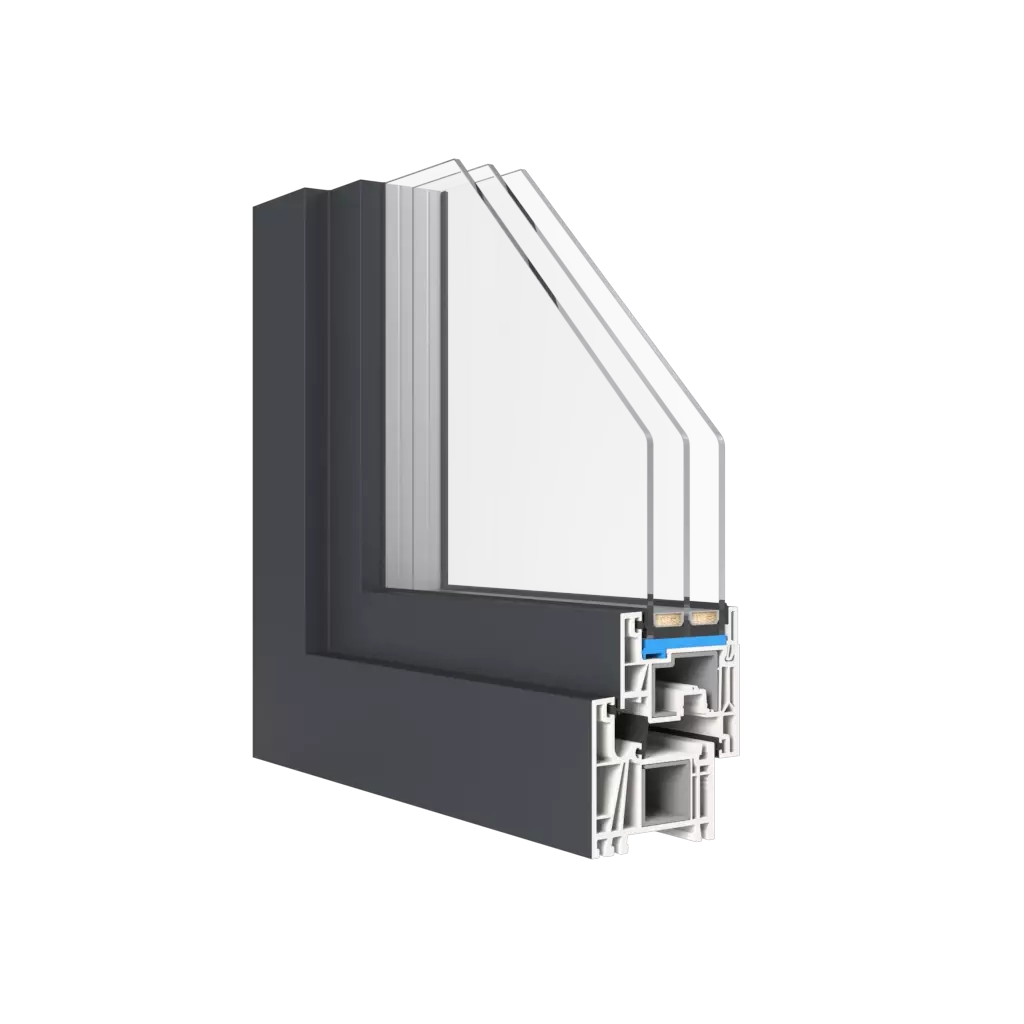

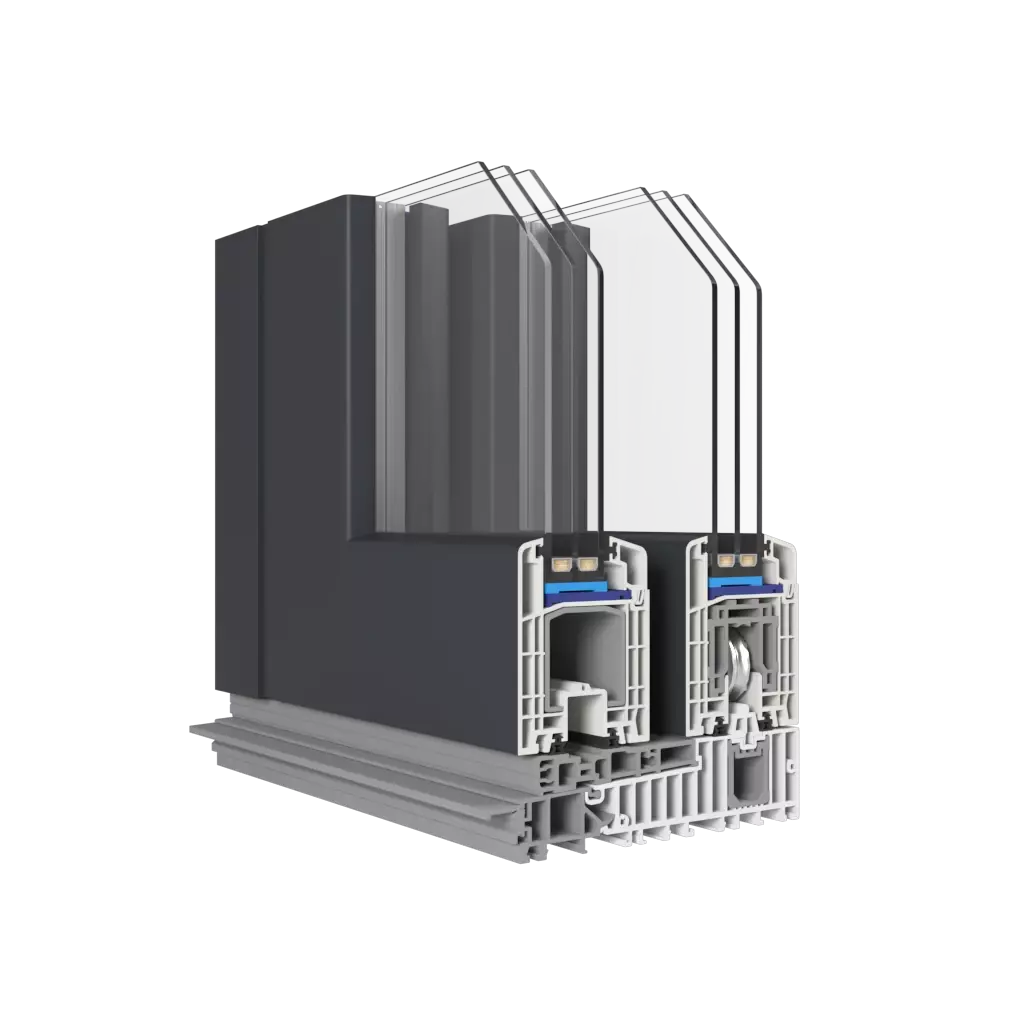

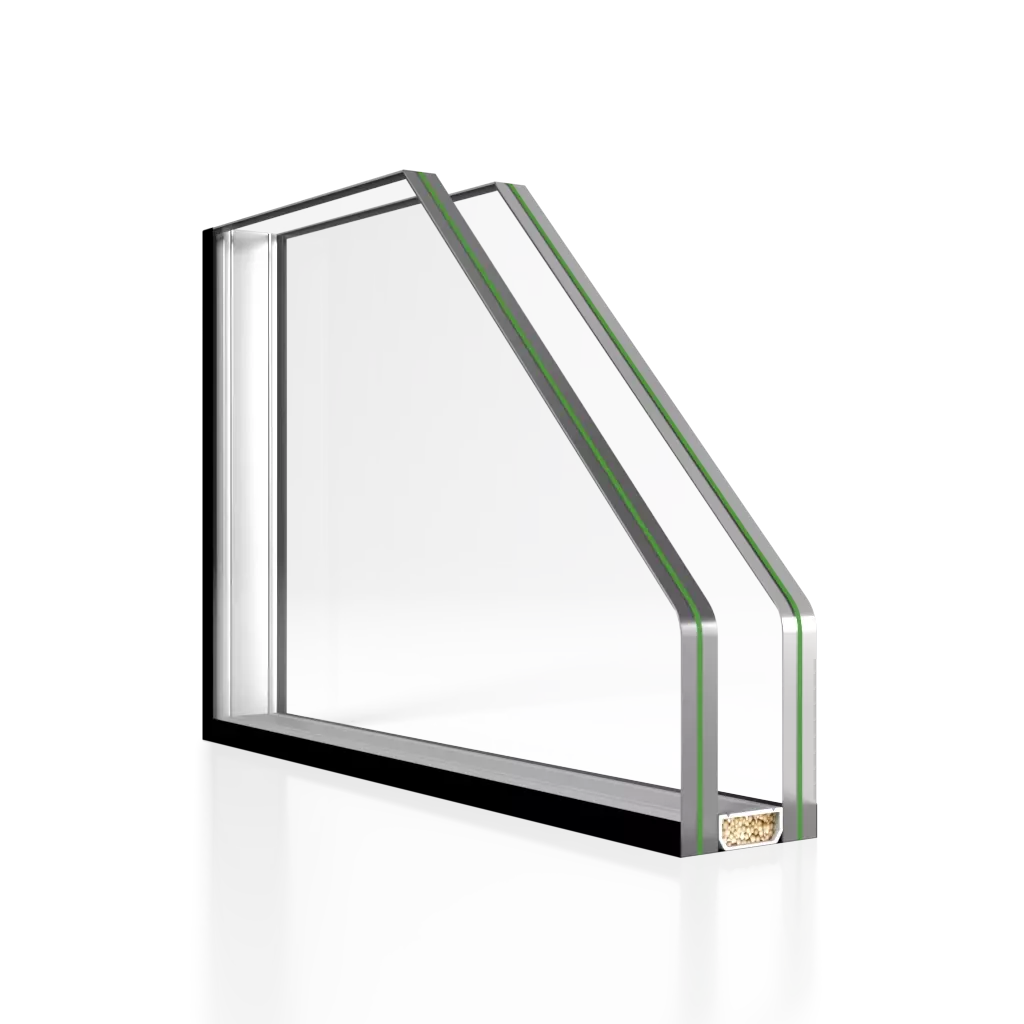

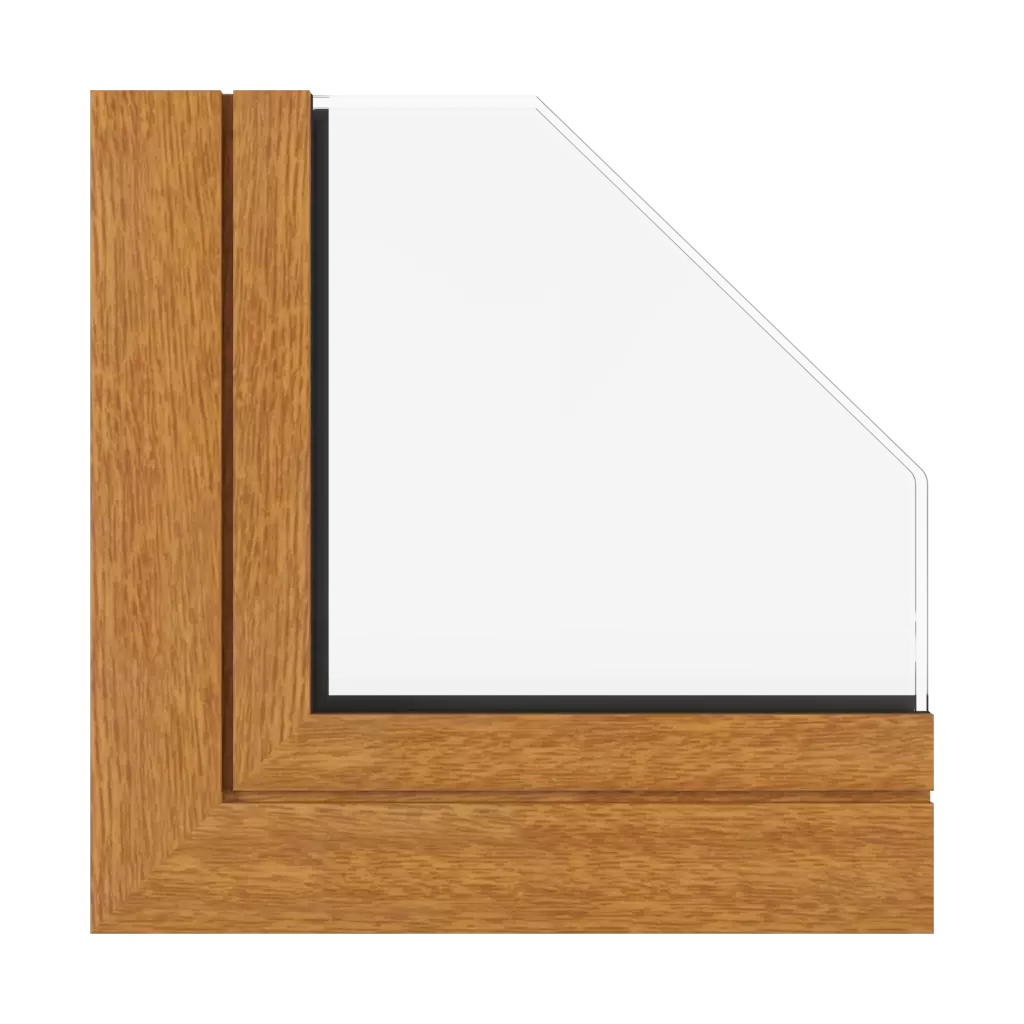

Available in double and triple glazing variants

Popular colors

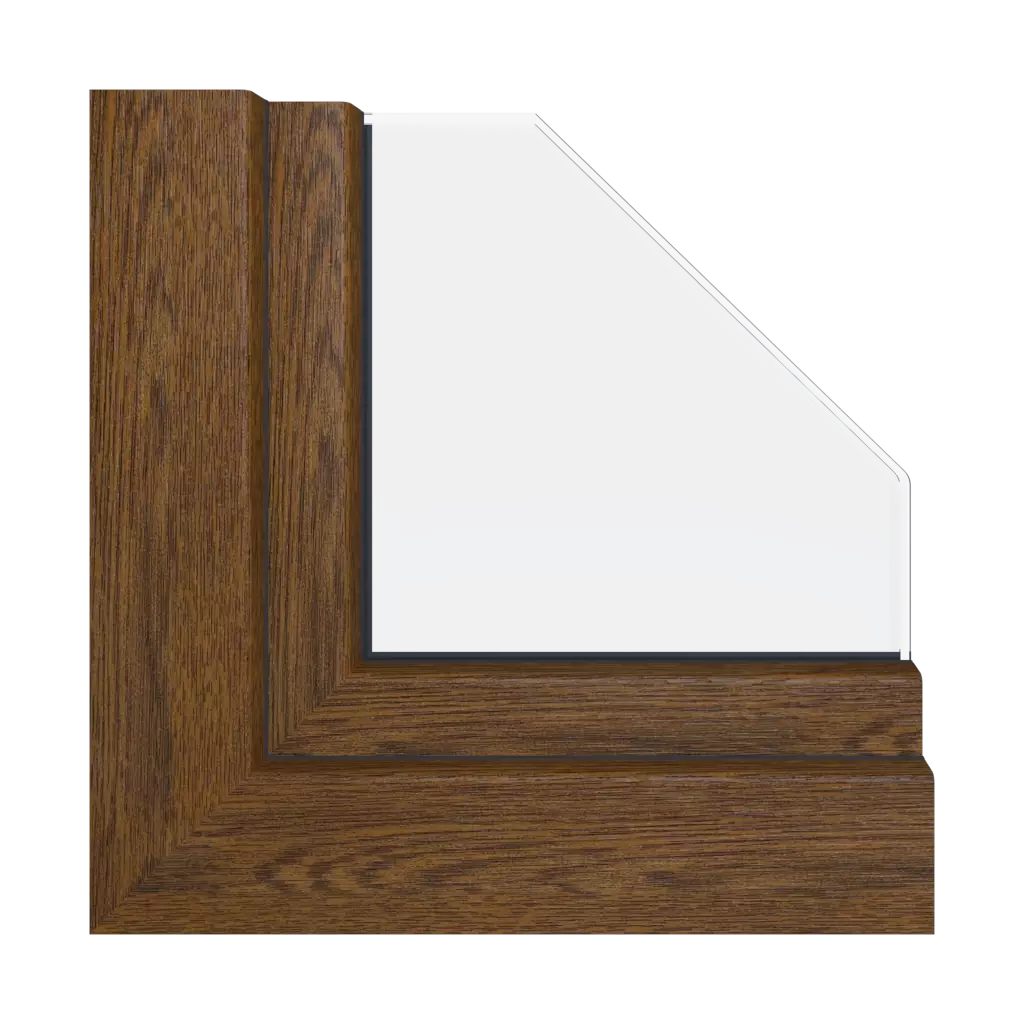

SK Golden Oak ✨

More

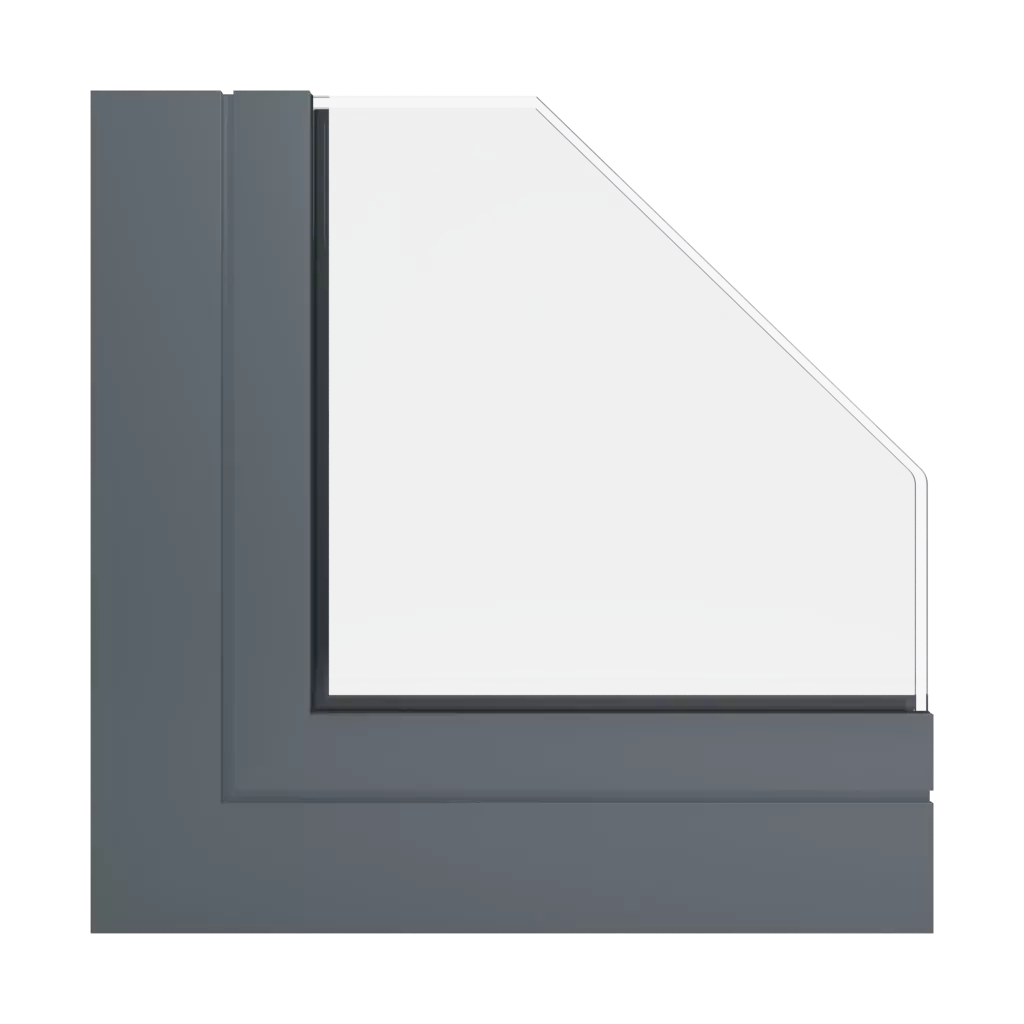

Gray anthracite SK ✨

More

White SK ✨

More

Jet black matt ✨

More

Anthracite grey matt ✨

More

Traffic white matt✨

More

Turner oak ✨

More

Mahogany ✨

More

Walnut ✨

More

Golden oak ✨

More

Bright concrete loft view ✨ 🆕

More

Dark concrete loft view ✨ 🆕

More

Walnut wood effect ✨

More

Classic golden oak wood effect ✨

More

RAL 9016 Beskid white ✨

More

RAL 9005 deep black ✨

More

RAL 8028 brown ✨

More

RAL 7021 grey black ✨

More

RAL 7016 Anthracite Gray ✨

More

RAL 7012 basalt grey ✨

More

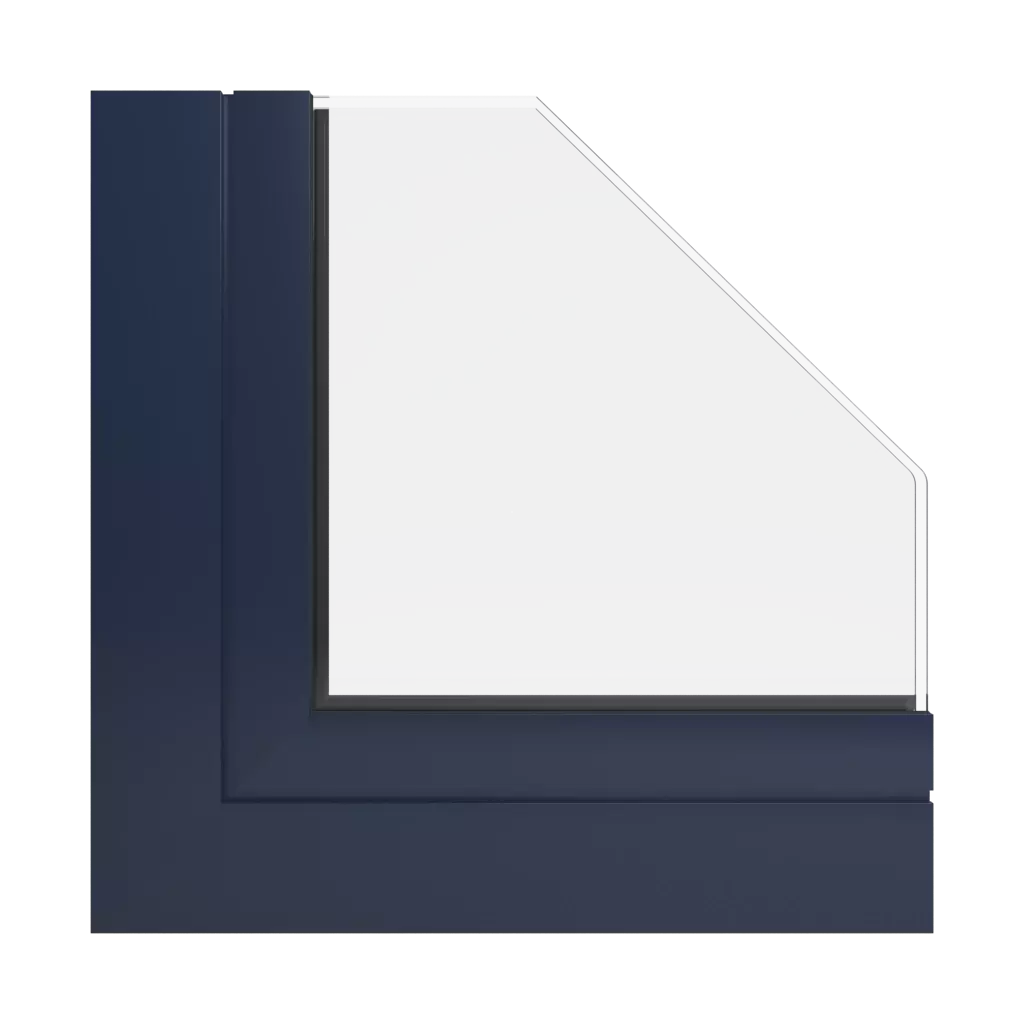

RAL 5011 steel blue ✨

More

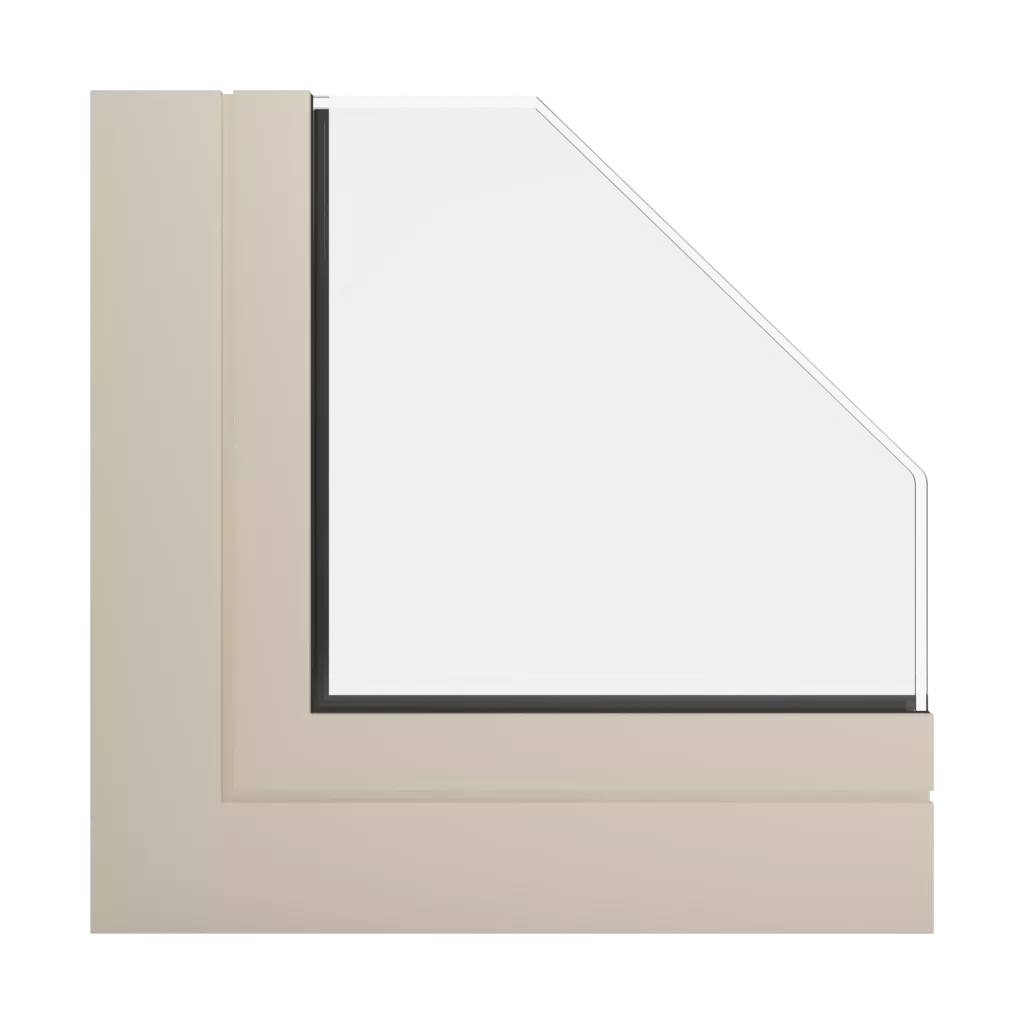

RAL 1015 creamy beige ✨

More

Walnut ✨

More

Golden oak ✨

More

Winchester XA ✨

More

Colors of window seals

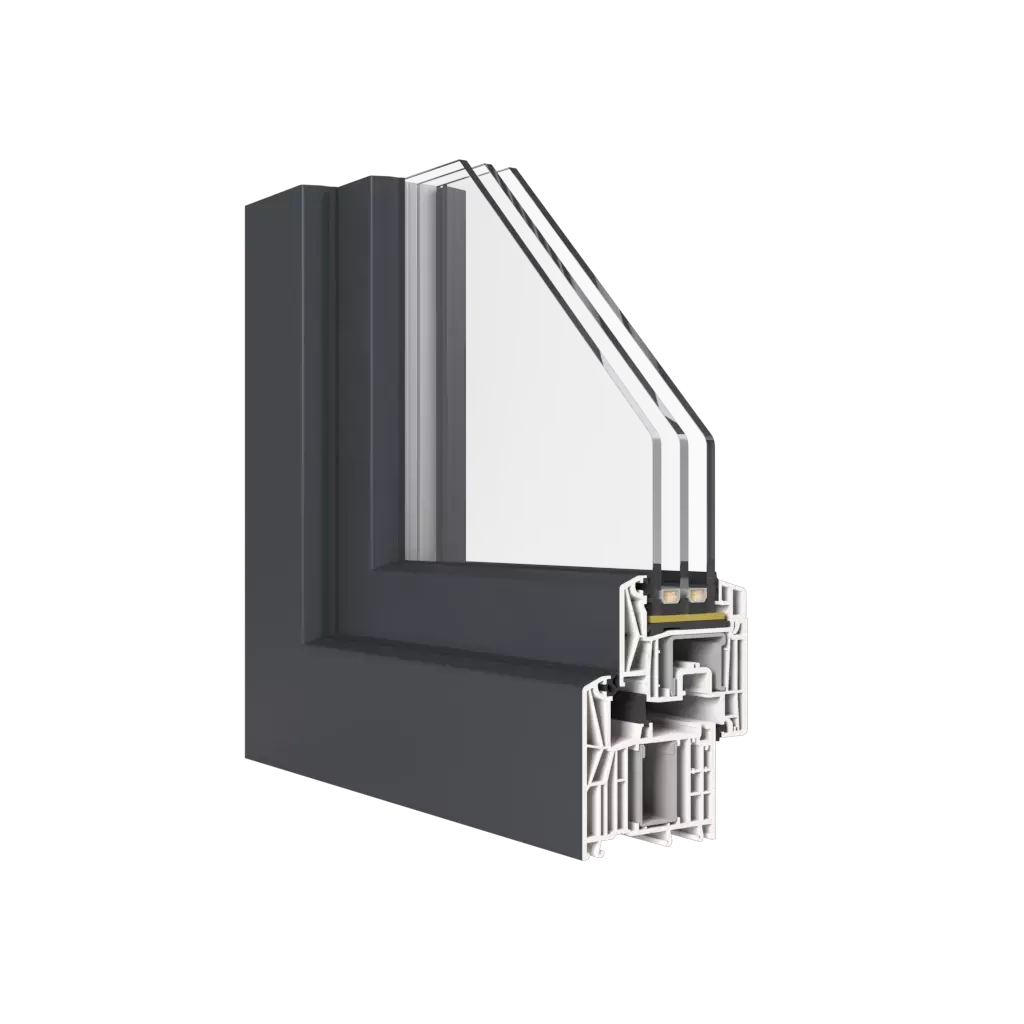

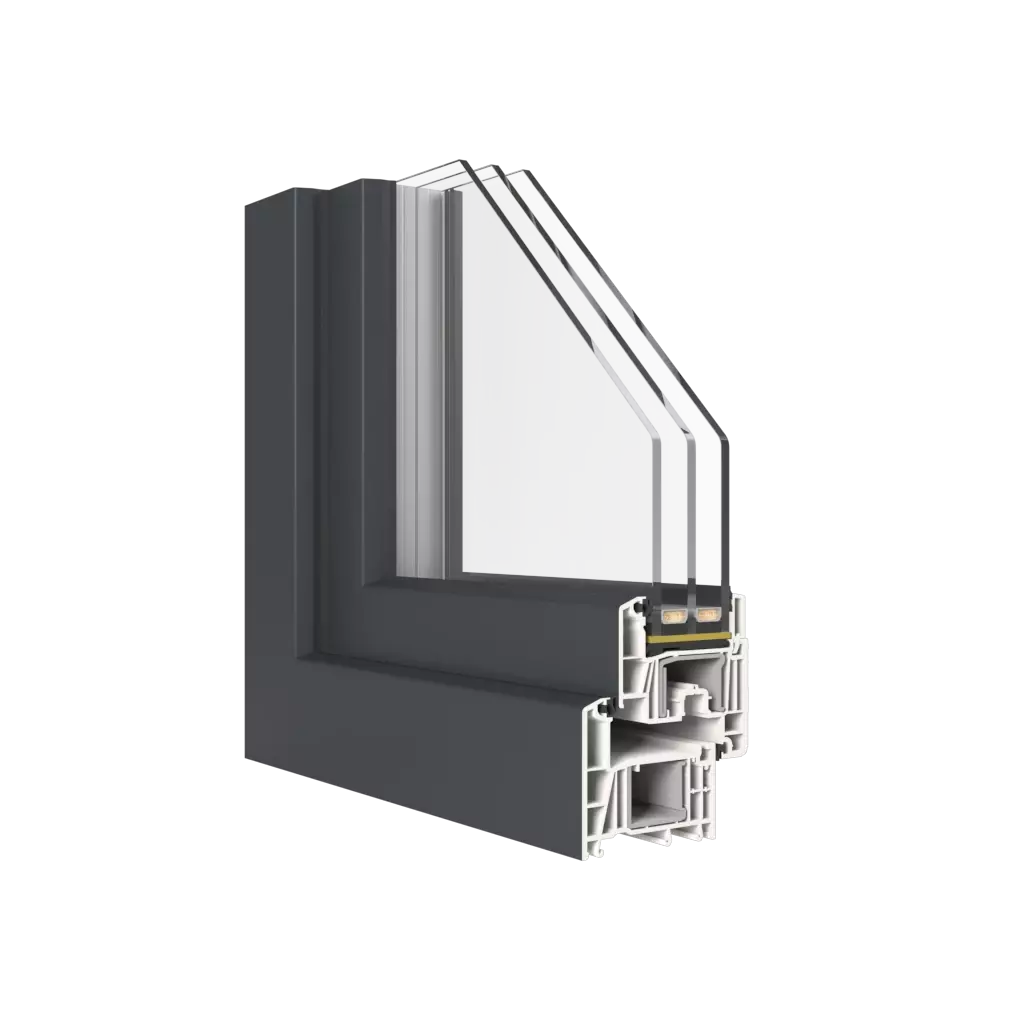

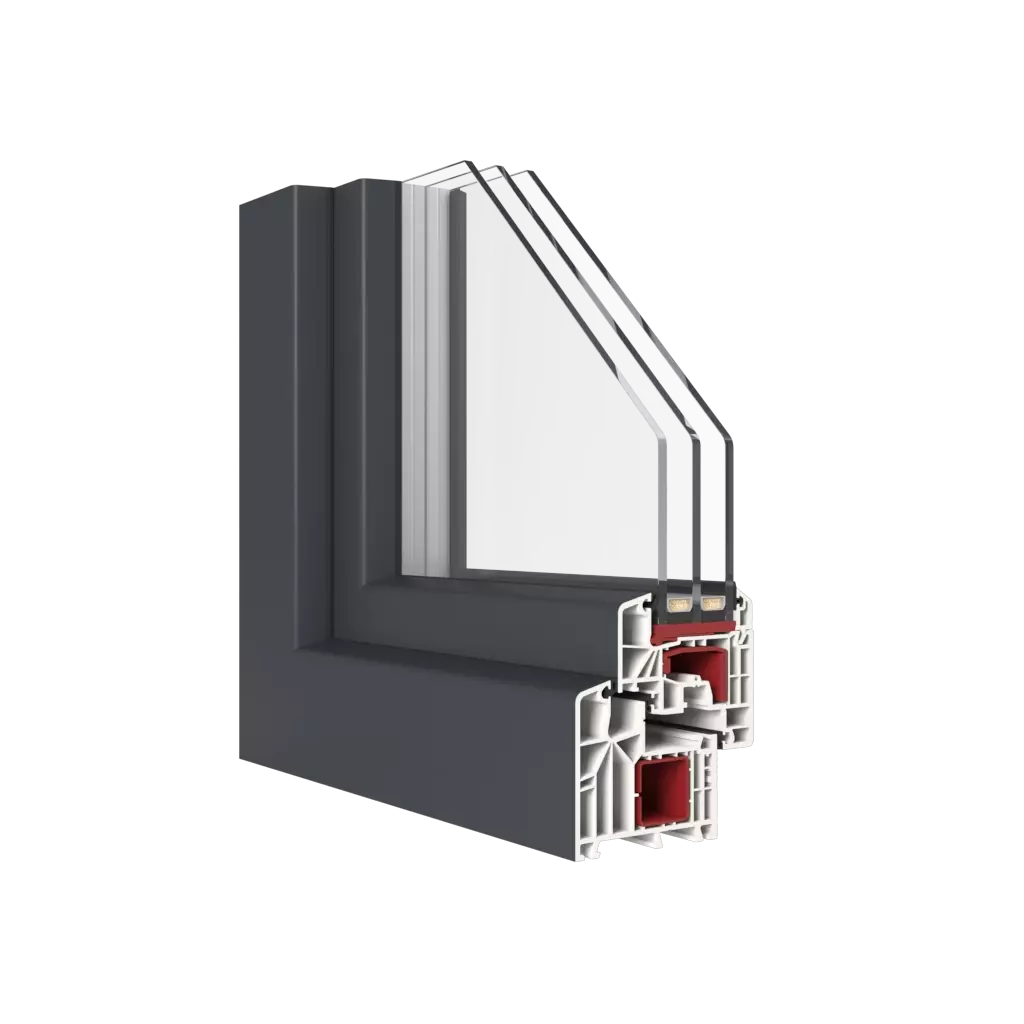

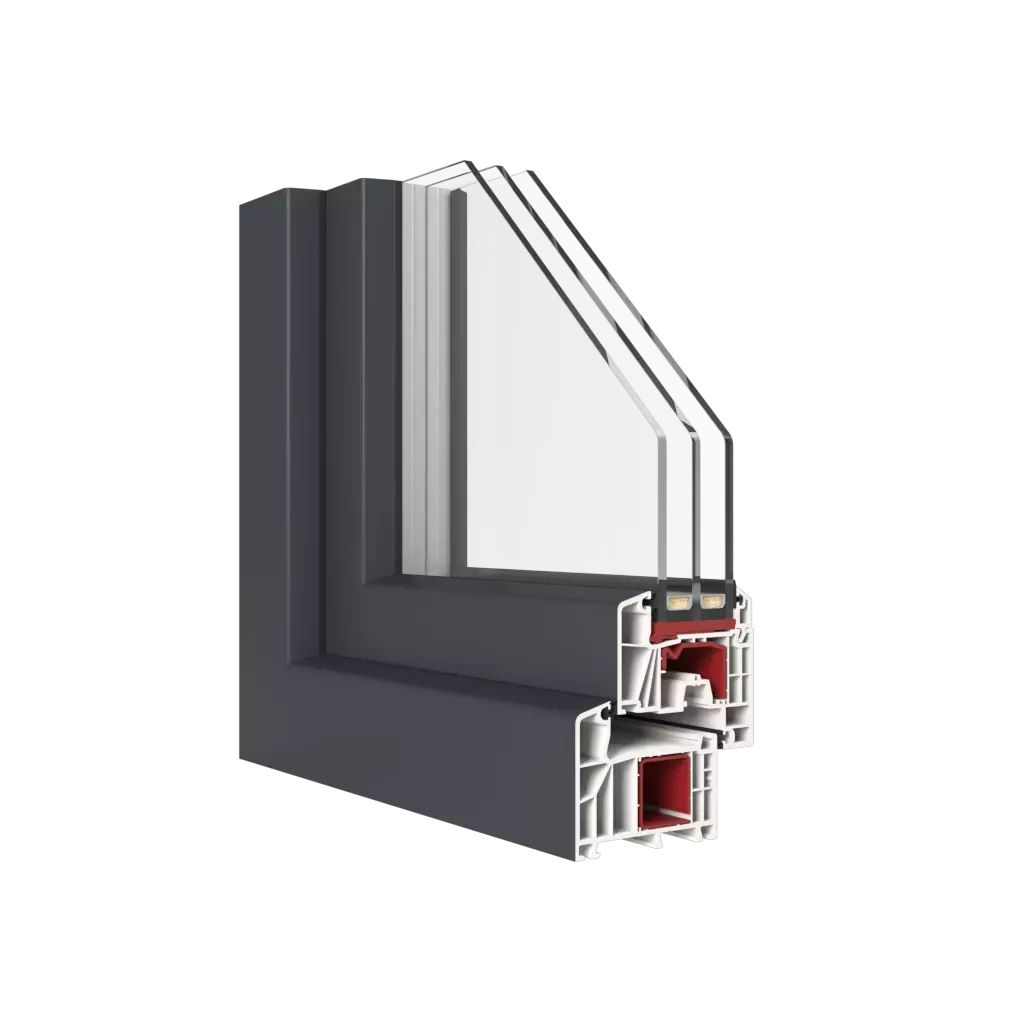

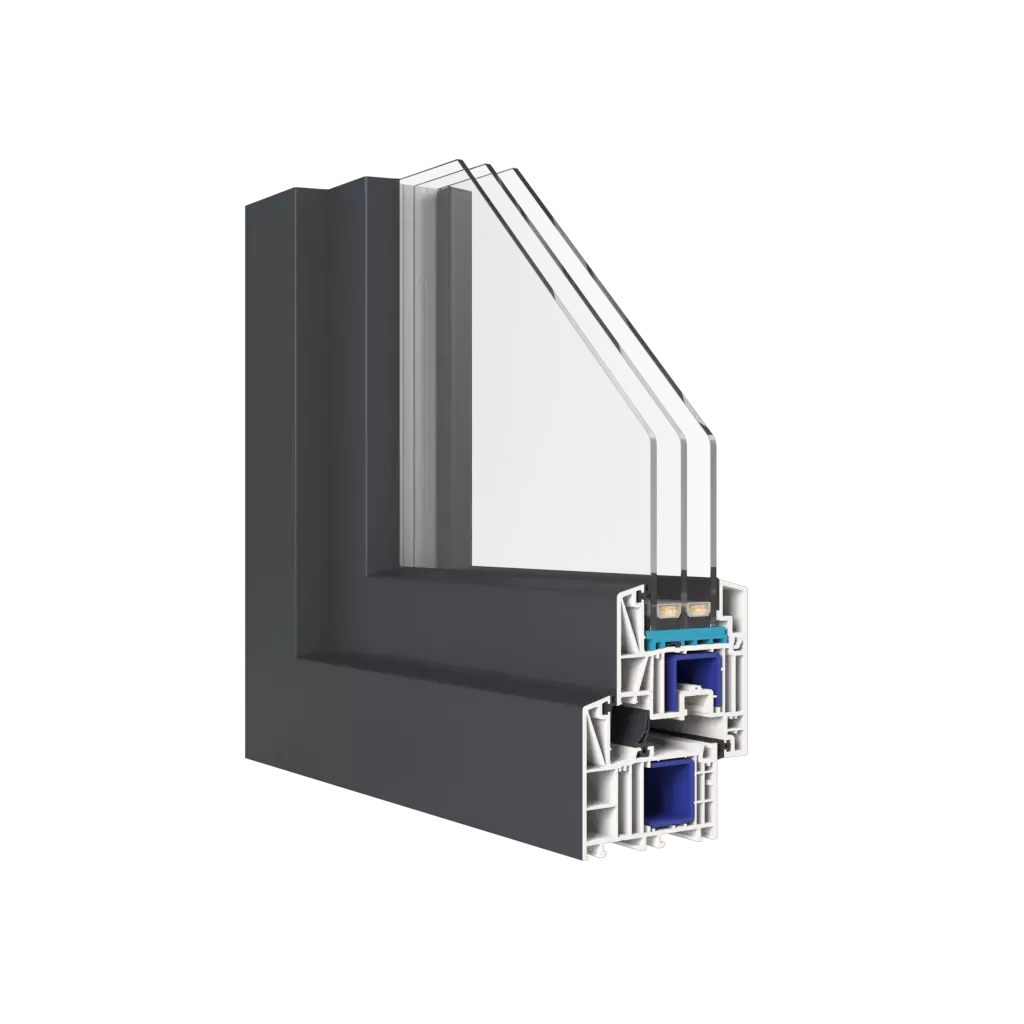

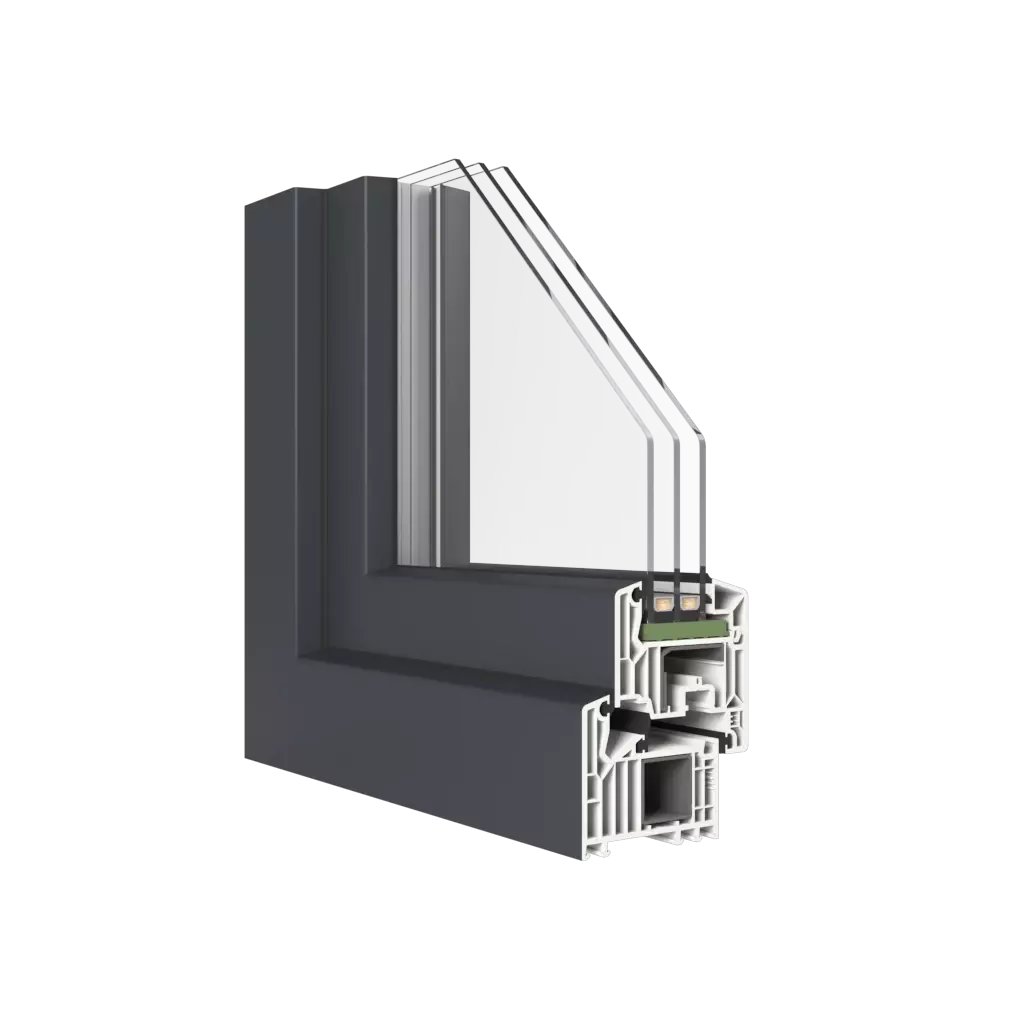

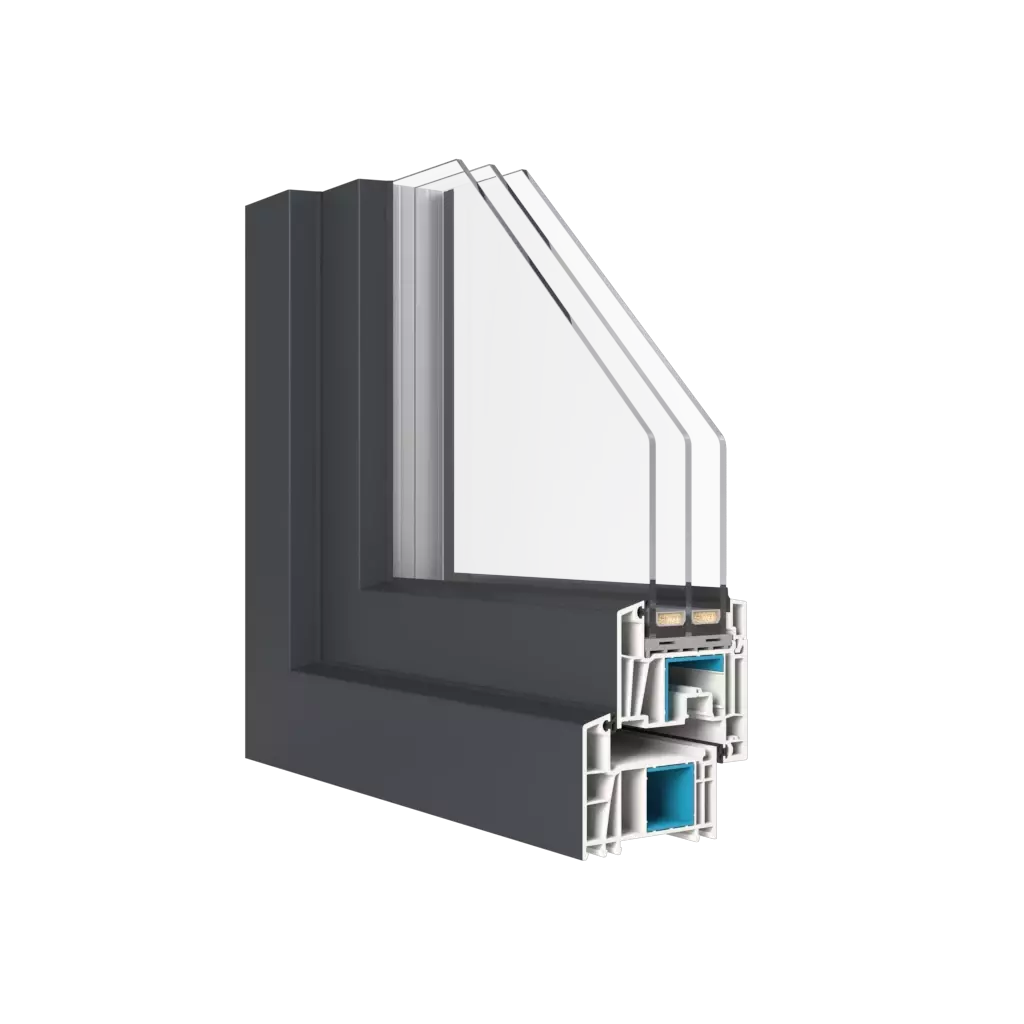

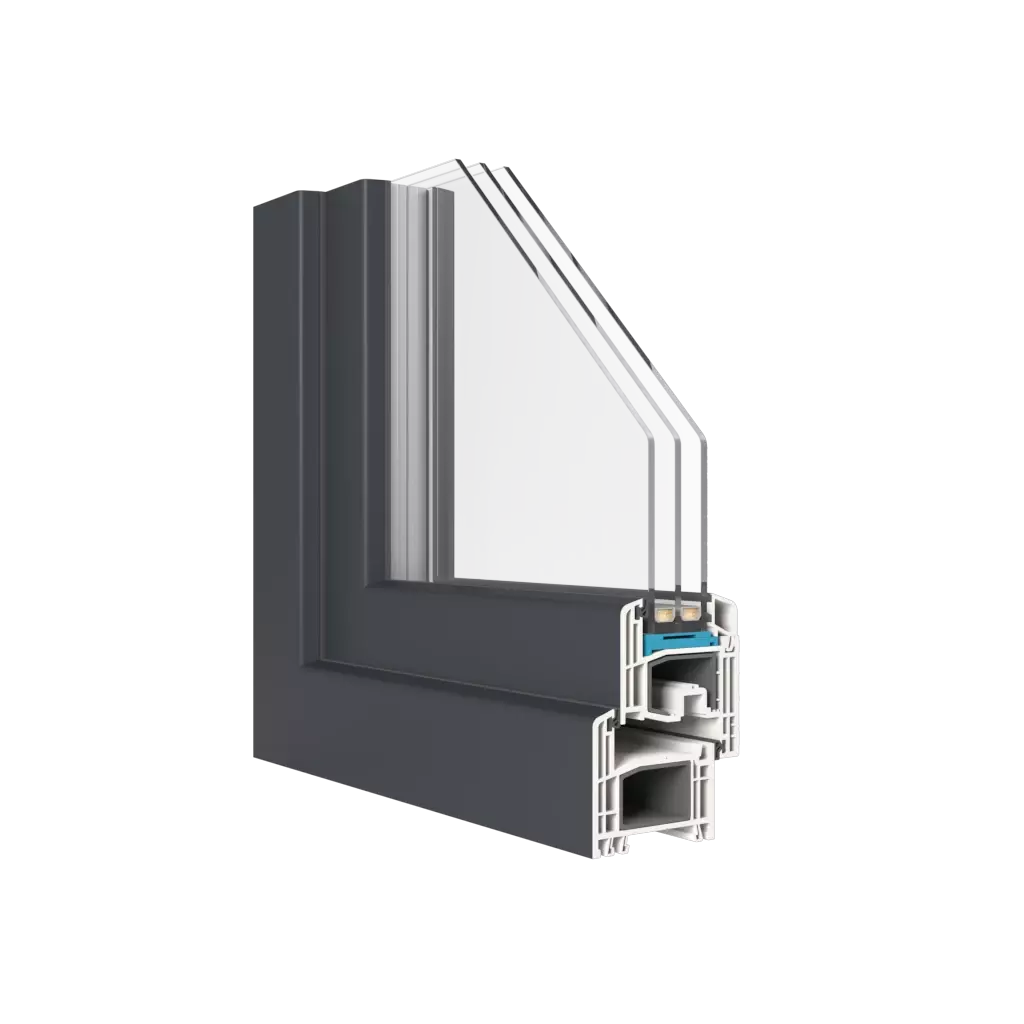

Popular PVC profiles

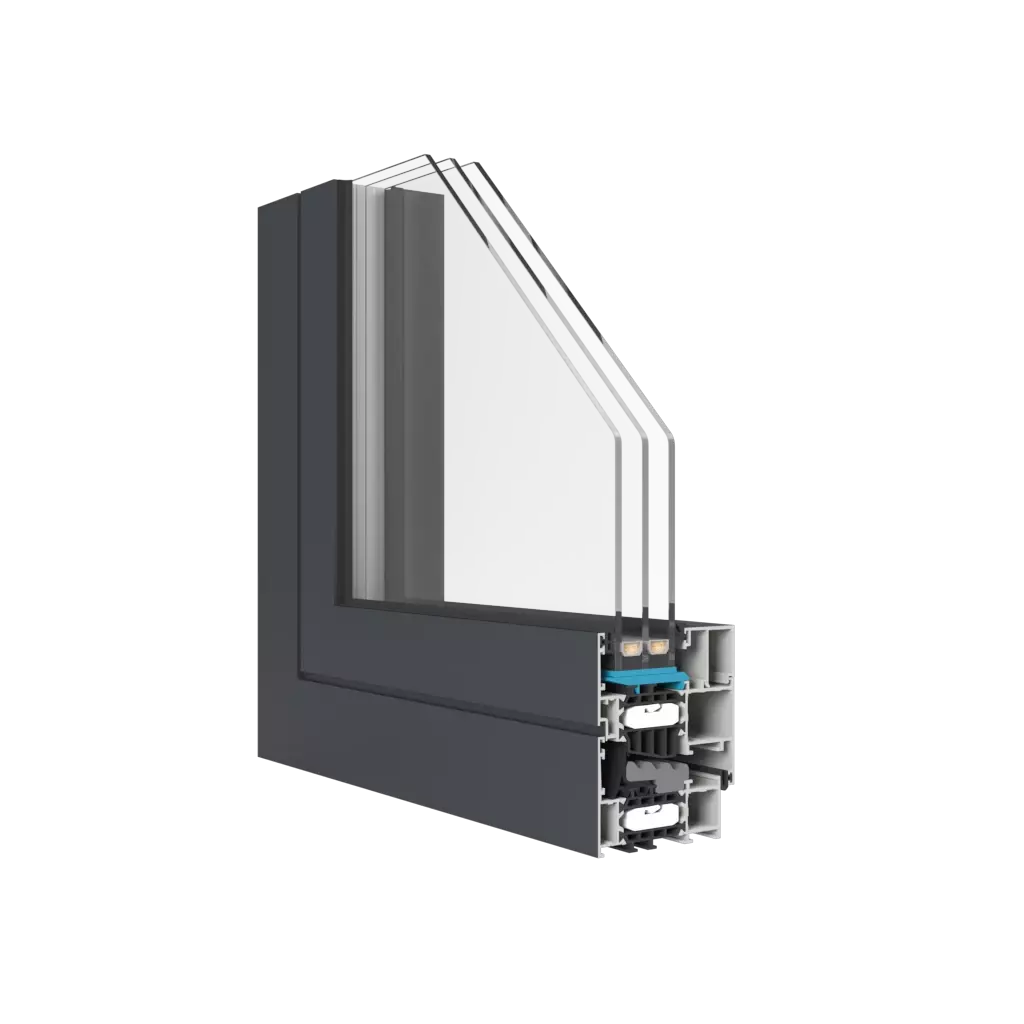

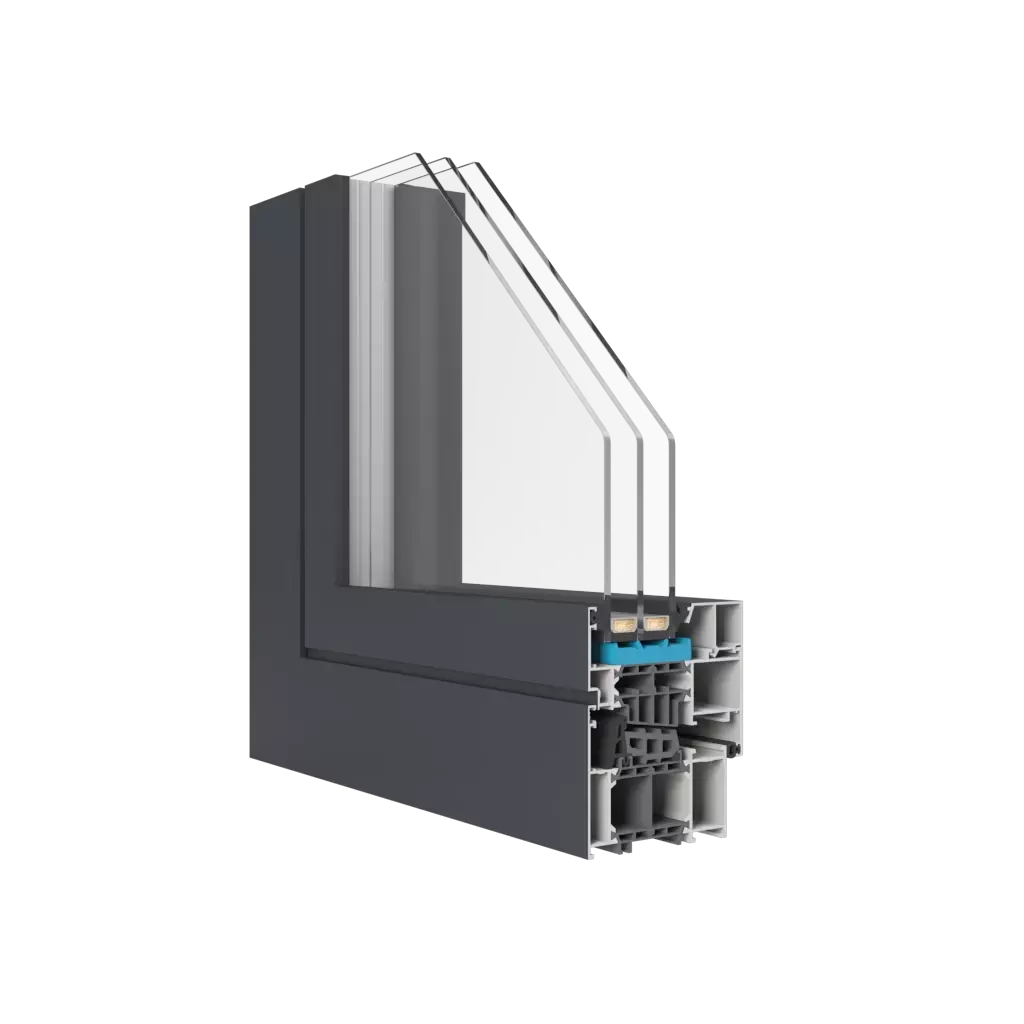

Popular aluminum profiles

Window accessories

Opening from the floor

More

The second handle on the movable mullion

More

Window diffusers

More

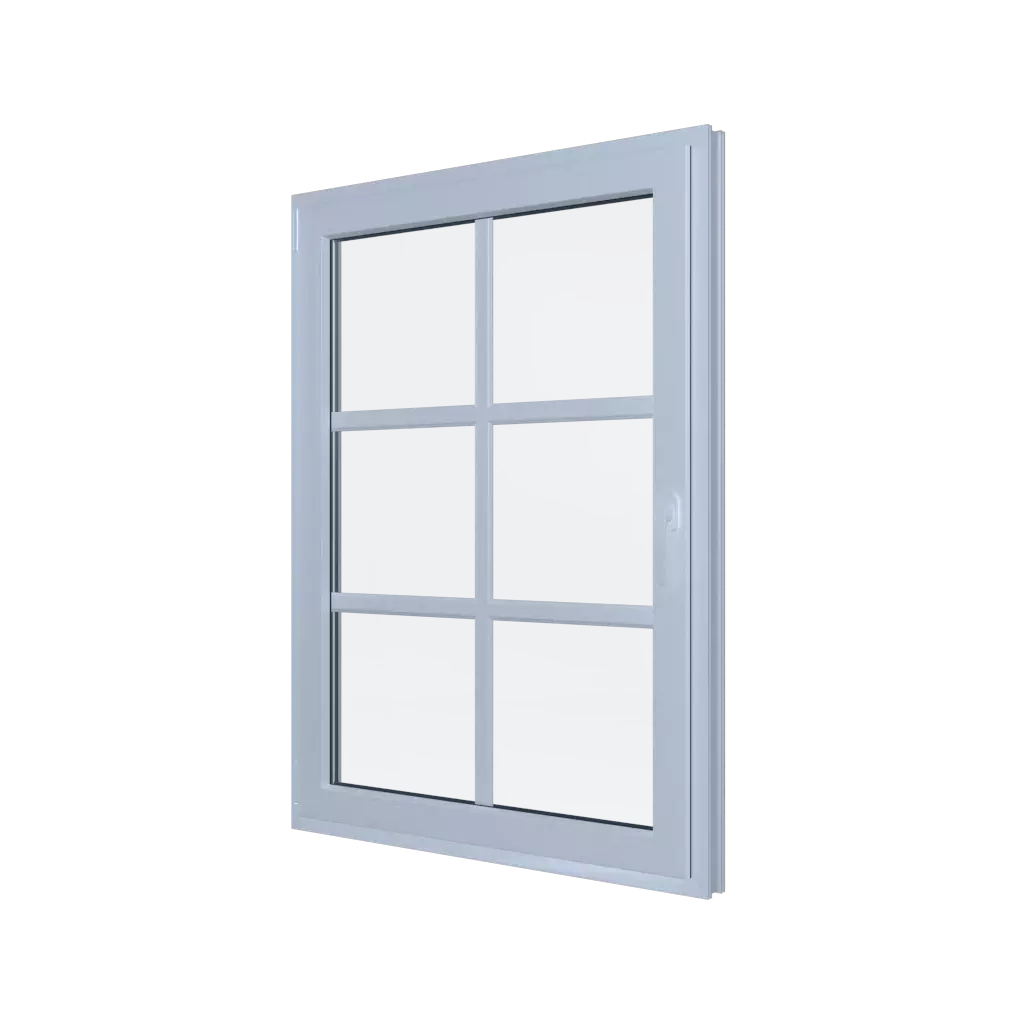

Muntins

More

Low threshold

More

Brake in the handle

More

Blockade of incorrect position of the handle

More

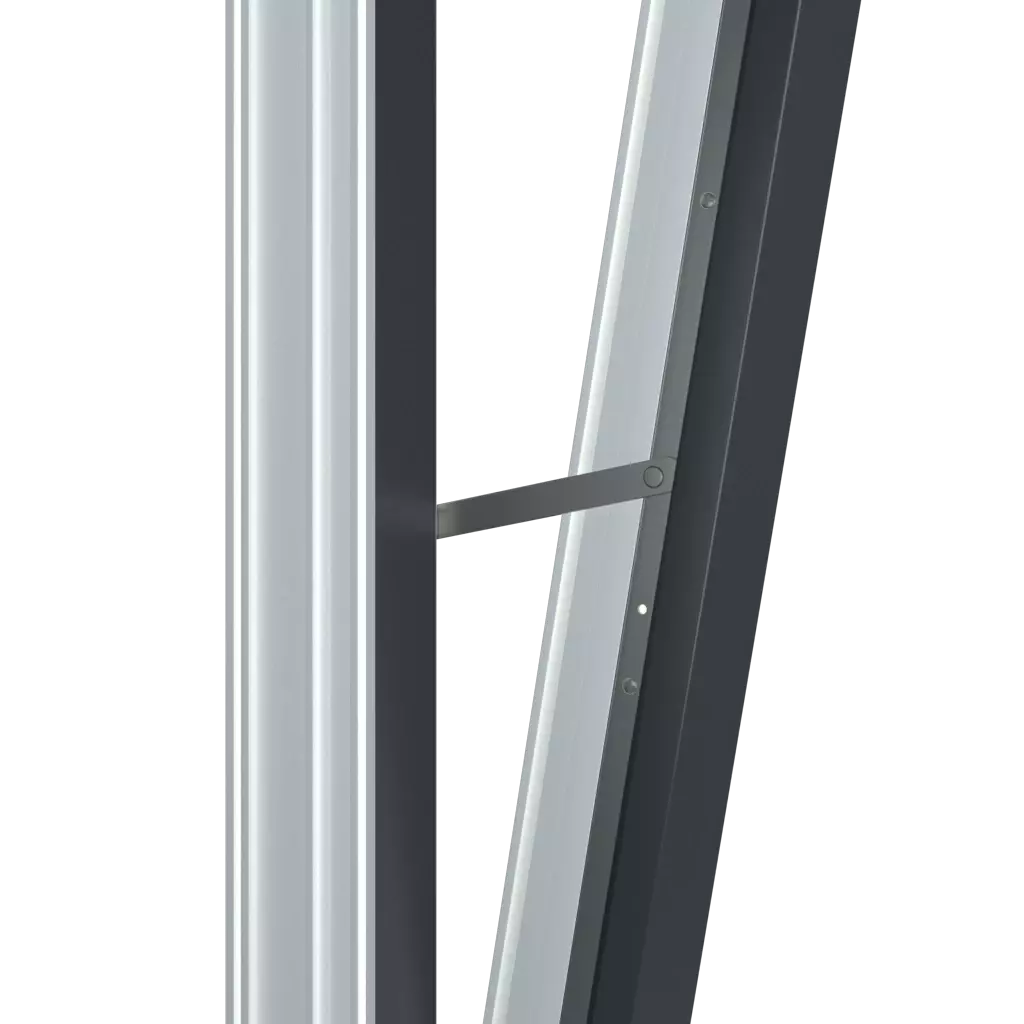

Tilt limiter

More

Temporary handle for renovation

More

Graduation of the tilt

More

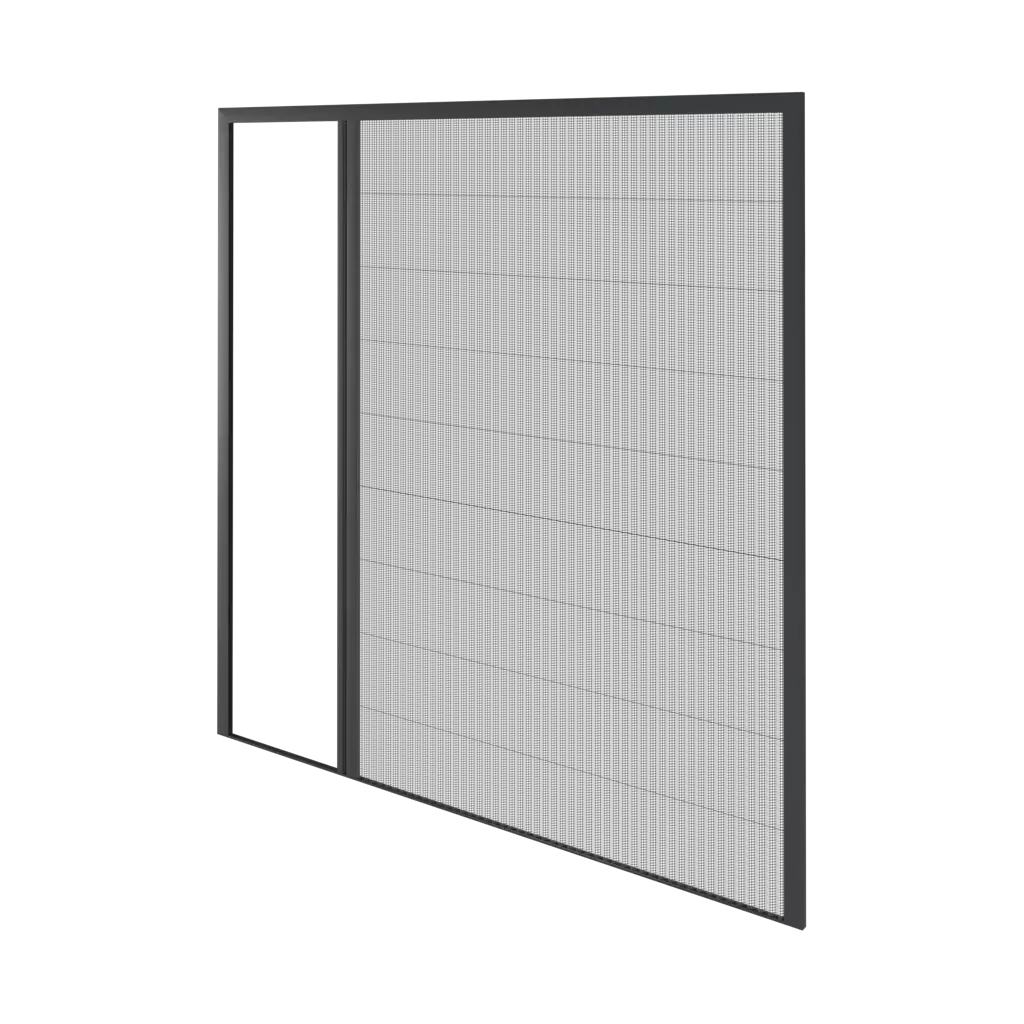

Insect screens

More

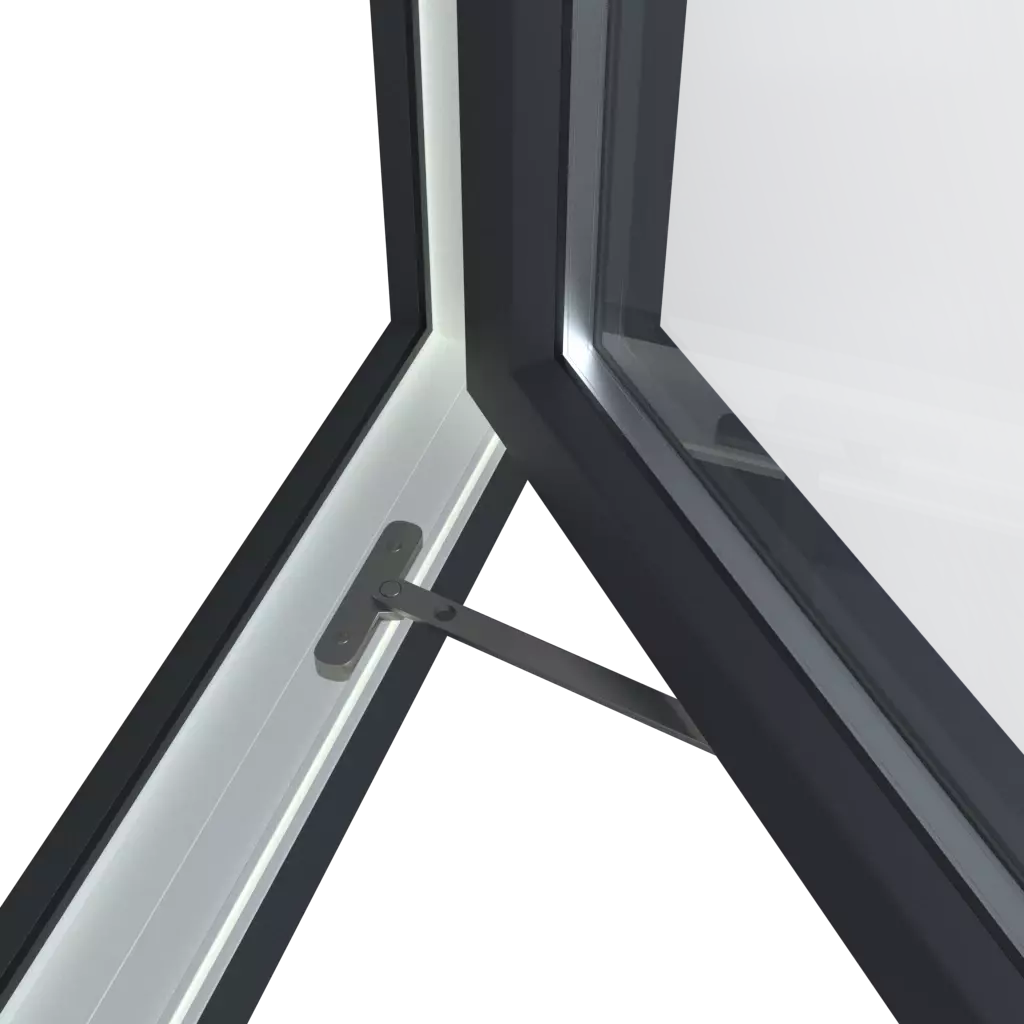

Hinges

More

Concealed hinges

More

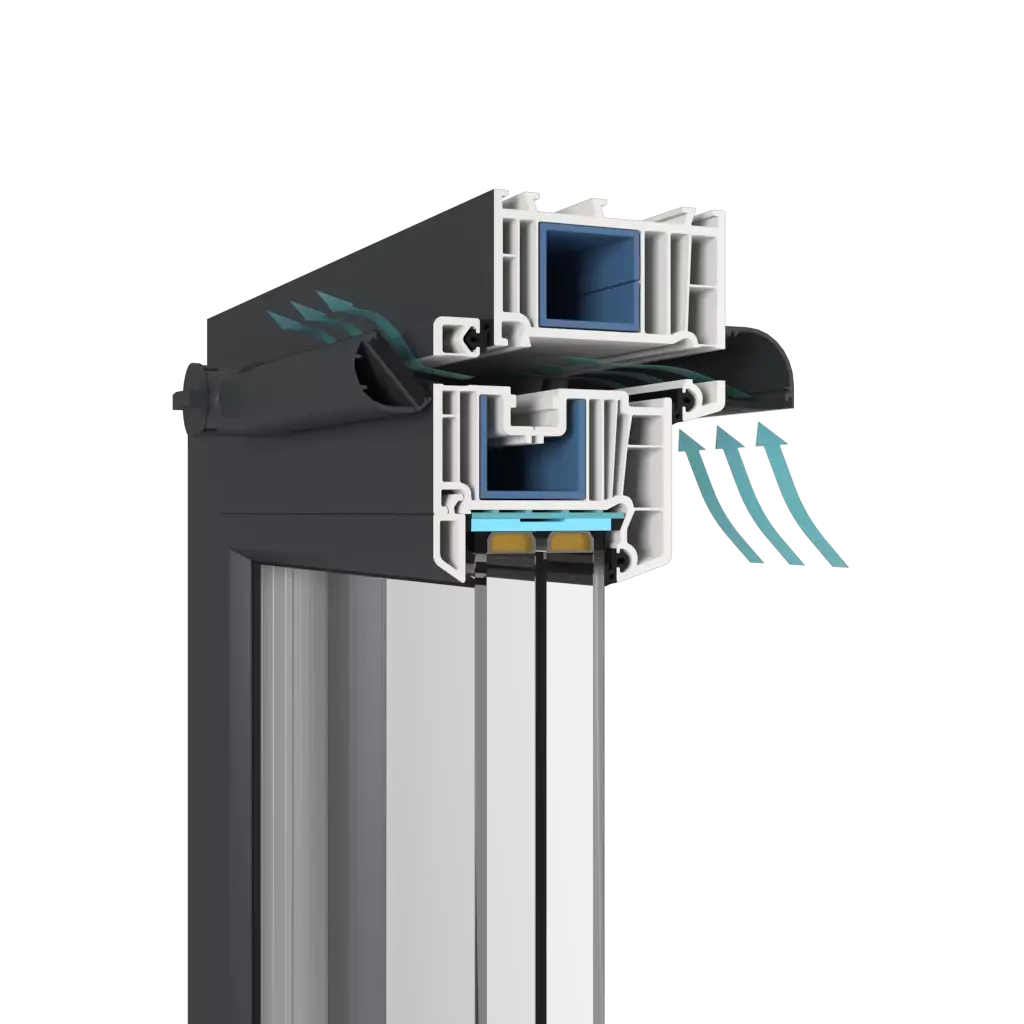

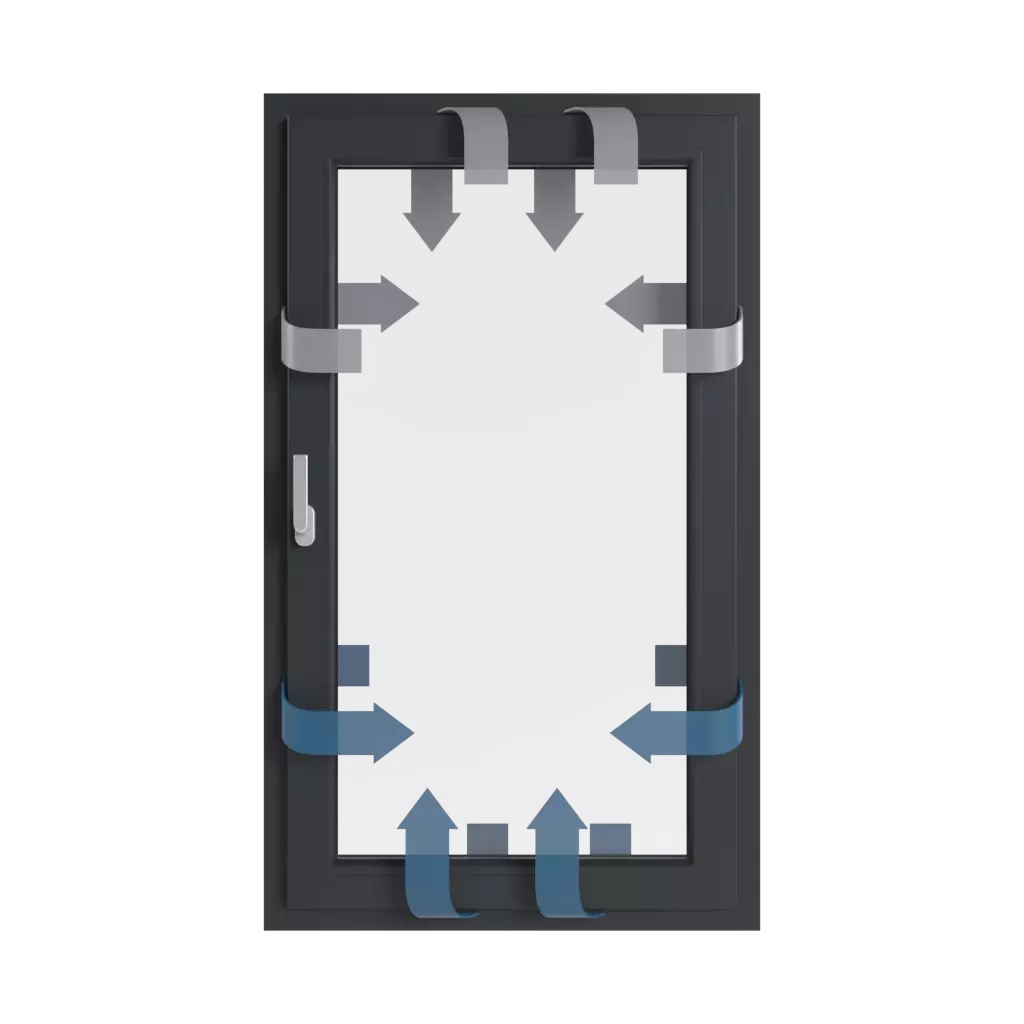

Microventilation

More

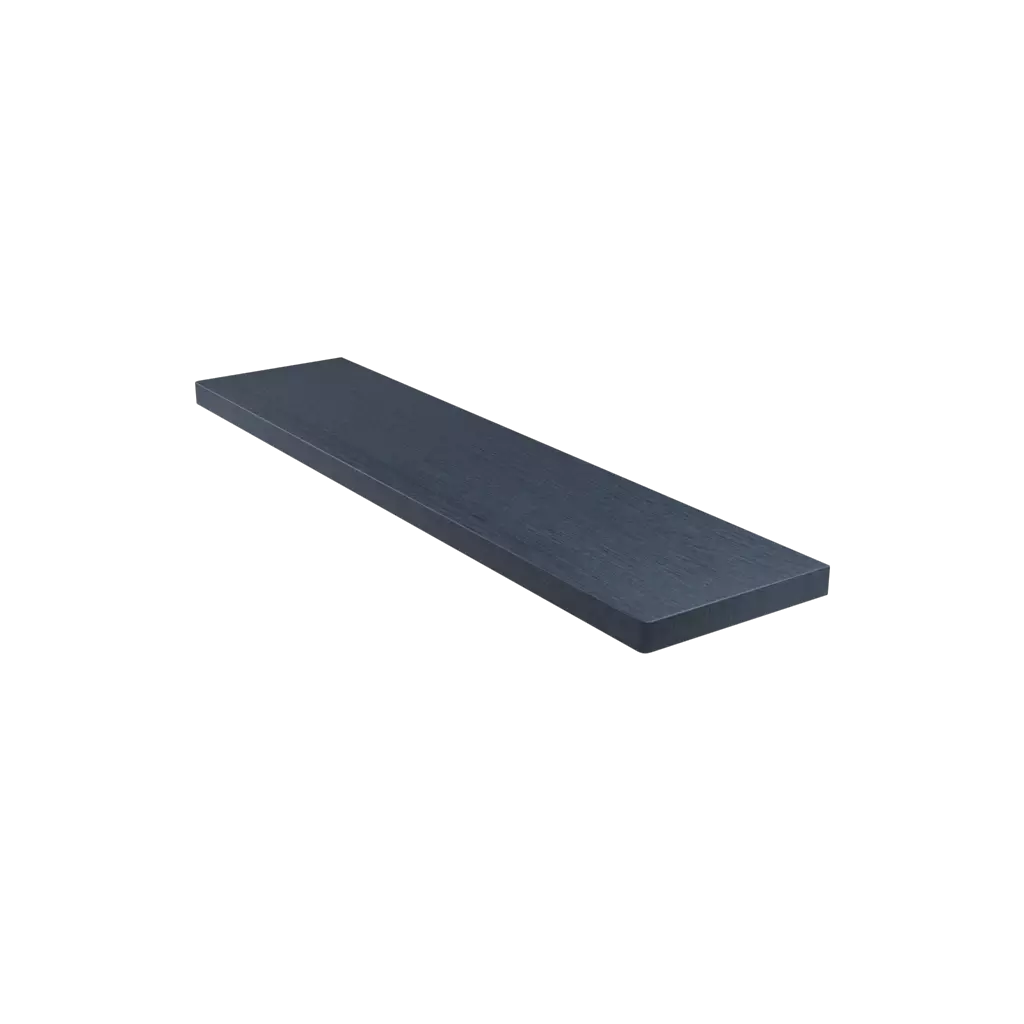

Sills

More

Facade blinds

More

Roller shutters

More

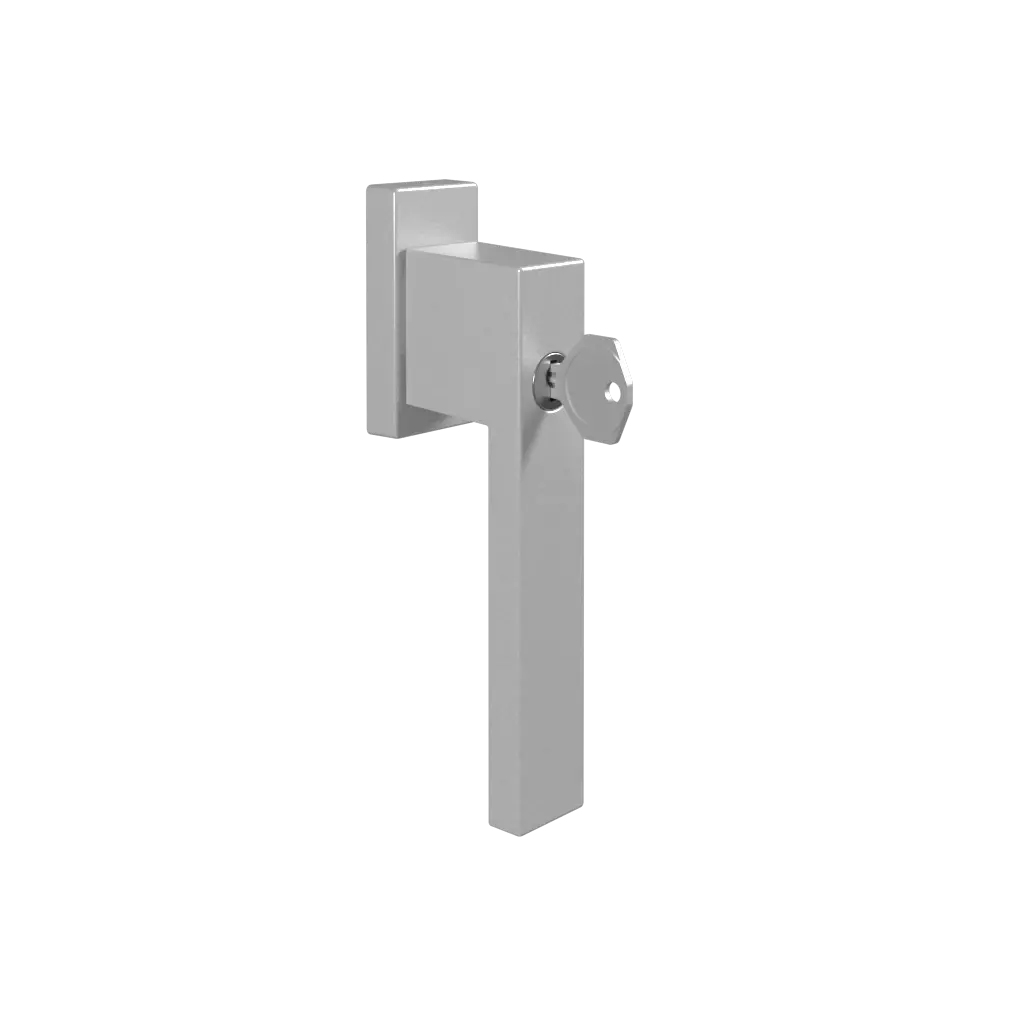

Handles

More